The standard ignition system in SR20DET engines is quite good. It features coil on plug ignition instead of a distributor (SR20DE) . Most misfires and other problems come from the age of the components rather than an inherent design deficiency.

Spark System

The ECU references its internal tables and sets a target ignition timing for a given load and RPM. It then creates a signal to stimulate the coil pack and fire the spark plug at the correct time.

From the FSM:

The ignition signal from the ECM is sent to and amplified by the power transistor. The power transistor turns on and off the ignition coil primary circuit. This on-off operation induces the proper high voltage in the coil secondary circuit.

The key concept of the ignition coil is that it is a step up transformer. It actually has two coils inside. There is a huge difference in the amount of windings in these primary and secondary coils. The primary coil receives current and creates an electromagnetic field. Once this current is removed, the magnetic field breaks down and the secondary coil, which has many many more windings than the primary, converts the energy to a voltage in the tens of thousands range. For example, if the secondary has 100 more windings than the primary, the spark will be 100 times the initial voltage. Enough to create a strong enough spark in the heat and pressure of the combustion chamber.

It’s important to note that while current through the ignition coil charges it, it discharges automatically once that input current is removed. This means the ECU needs produce its signal to start the charging BEFORE it wants the actual spark to occur. Each brand of coil has a set ‘dwell’ time for this. If the ECU uses too short a dwell, the coil will not have charged enough energy, if the ECU uses too long a dwell time, the coil may be over charged, over heated and be damaged.

The ECU produces a 5 V signal that is not strong enough to energise the primary coil sufficiently. Even if it were, the resulting high current through the ECU pin would damage it. Therefore, the signal pin from the ECU for each cylinder feeds into a power transistor, commonly called the igniter chip. The 5 V signal from the ECU is used in this transistor to switch the 12 V power supply to the primary coil. A 12 V input is always supplied to the primary coil, but the circuit is incomplete until the 5 V signal causes the power transistor to connect ground. This explains why the power transistor is said to be an amplifier. It uses a 5 V signal to send 12 V to the coil packs.

The igniter chip is simply a set of transistor switches for completing the circuit. They cannot be upgraded for ‘more power’ because all they do is act as a switch. It either works or it doesn’t. A failure would necessitate replacement, perhaps to a unit from another car because of convenience or availability. There is no such thing as a more powerful unit.

A really long but really good video exists that breaks down the entire ignition system of the engine. It starts with old school points style distributor based systems, and then covers more modern coil on plug systems. It’s Australian too.

Differences in S13/14 to S15 SR20DET

S13/14 have what can be referred to as ‘dumb’ coils, as they require an external igniter chip. S15 have a ‘smart’ coil, as the igniter is inbuilt into each coil pack, meaning the raw ECU signal can be wired to them directly. It should be clear then that S15 coil packs are not compatible with earlier model SR20DETs due to this.

The S14 ignition schematic below shows the power transistor unit in place. You can see that the 12 V feed comes from the bottom black line, through the primary coil (left hand squiggle in coil packs), and into the power transistor. The small black arrows show the flow of current from positive (12 V) to negative (ground):

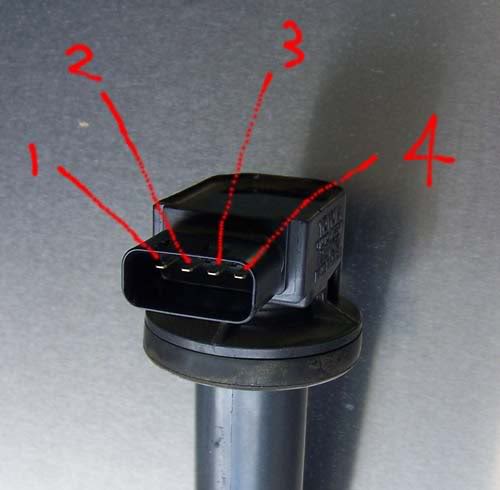

The S15 ignition schematic shows a lack of separate power transistor. The ECU signal wires go straight to the coil packs. The power transistor is inside each coil pack. When 5 V is received on pin 3 and grounded on pin 2, it switches the transistor on and allows the 12 V input from pin 1 to travel through the primary coil (upper squiggle) and also ground on pin 2.

Misfires

Many cars develop a miss as they wind in additional boost. This is known as ‘blowing out’ the spark. The easiest fix is to gap the spark plugs narrower, so that less electrical energy is required for the spark to bridge the gap.

Many claim that a new set of factory coil packs can support high boost and power, so it’s likely that the units that misfire have a perished section of insulation. The spark travels sideways through the unit to the head rather than going through to the spark plug. The spark simply finds the path of least resistance. It only takes a tiny crack or split to induce this, so visual inspection might yield no result.

My grey 180 never had any issues with misfires at 220 rwkw. The components probably weren’t old enough. The white Sileighty has slowly developed a misfire, however, probably due to the age of the coil packs. I was after a solution that was cheap, not too hard to install and at least as effective as a set of new, factory coil packs.

Option 1 – Replacement Factory Coil Packs

These are available from Taarks for $126 each. Straight plug and play replacement, super easy. Likely to support high boost with gapped down plugs for thousands of kilometres.

Option 2 – Spitfire/Yellow Jacket replacement Coil Packs

These are also plug and play. The Spitfires are a pretty blue colour but internet wisdom says they are not actually any stronger than factory. There are also mixed reports about reliability with stories of dead on arrival units. Some people claim to have gotten better results switching back to new factory coils. Available for $169 each from Just Jap.

Yellow Jackets are cheaper alternative available by searching on eBay.

Option 3 – LS Coil Packs

These coil packs are ‘smart’, and pack a lot of electrical punch. They are also fairly cheap, around $130 each from eBay. The pick is the ‘LS2 truck’ unit, called the LQ9. They are high output and have a built in heat sink. The trouble with any LS coils is that they are not coil over plug (‘COP’), which means they won’t fit snugly inside the rocker cover. Instead they will need to be mounted on some sort of custom bracket, with spark plugs leads routed to the top of each spark plug:

https://lh3.googleusercontent.com/-7QwkmpGy4LY/TirjM7NBoCI/AAAAAAAAAdQ/FTp11Vb0mKI/s640/DSCN0568.JPG

Option 4 – Yaris 1NZ Coil Packs

Toyota coilpacks from Yaris 1NZ and similar engines have a similar size to the factory Nissan units. They are ‘smart’ coils, with the igniter built in. They should be readily available for a long time to come because they are from a much newer car. Best of all, they are very, very cheap. Goleby’s Parts have a kit with four new coil packs, new plugs and little adaptor brackets for $270.

http://www.golebysparts.com.au/uploads/shopEasy/products/images/1ygldlzwpr.jpg

Other late model coil packs might be suitable as well. Ultimately all that needs to match is the shape. If they have a built in igniter, then the wiring will always be 12 V, ground and a 5 V ECU signal. Newer coil packs have a strong spark to help with modern emissions standards. Ensuring the air/fuel mixture is completely combusted helps with emissions, so even non performance cars such as the Yaris will have high power coil packs.

My Choice: Yaris

I couldn’t go past the value of the Goleby’s kit. I addition to the value, Yaris coil packs are said to support comfortably more than 100 hp per cylinder at over 20 psi boost. There is a detailed thread here which compares the late model Toyota coil packs. Searching Google will yield numerous results about how these have been used on high power 1JZ and 2JZ engines, as well as some serious SR20s. Goleby’s claim the upgrade is good for 1000 hp!

The only issues come around the wiring, with the factory igniter chip needing bypassing and the plugs needing changing in the coil pack harness.

Deleting the Igniter Chip

As the Yaris coils have a power transistor built in, The factory SR20DET igniter chip needs to go. The new coils are expecting a 5 V signal, so connecting them to the standard chip which aims to ground a 12 V current when switched by the ECU will not get us very far. It is the equivalent of connecting the new coil’s input signal to ground.

The cheapest way to eliminate the power transistor is to wire straight across it. The loom could be cut and soldered either side of the unit, or the unit could be opened, its internals removed and wires bridged from one side to another. Each wire goes straight across and the ground (labelled ‘G’) is ignored:

http://websitecre8.com/images/igniter.jpg

Instead of this, I found a bypass connector from a shop in the states: SR20DET Ignition Chip Bypass. Shipping and exchange rate brought it up to about AU $120, but you can’t beat the ease of install and reversibility.

http://cdn6.bigcommerce.com/s-b03t074/products/1724/images/7127/SR20ChipBYPASS__54985.1474173448.1280.1280.jpg?c=2

Modifying the Coil Pack Harness for the New Plugs

Another win for me was that I had previously purchased a spare coil pack harness for $40 second hand. This meant I could use it to cut and crimp the new 1NZ connectors to, leaving the original intact. Doing it this way ensures that the mod is reversible by reinstalling the factory harness.

The wiring for the new coil packs is as follows (from http://www.sq-engineering.com/tech-articles/coilpack-info-guide):

http://www.sq-engineering.com/media/wysiwyg/article-images/coilpack-2nz-connection.jpg

[Pin 1] Earth / common ground: This grounds each coil to the body / earth, an electric connection to to the cam cover alone is not at all suggested.

[Pin 2] IGT / trigger: The signal wire to activate the firing of the coil, triggered directly from the ECU’s ignition output. These can paired with another coil for a waste spark connection, for example using two ECU ignition outputs to run four coil packs. See the next section for more on this subject.

[Pin 3] IGF / ignition feedback: Used by OEM ECU’s to confirm the firing of the ignition coil. If a coil malfunctions the ECU will sense the lack of this fire confirmation and put itself into a fault / limp mode. This is not normally used at all with an aftermarket /stand-alone ECU and hence only three wires are used for each coil.

[Pin 4] Power (+) / ignition power: This is the main power supply for all of the coils, this power feed is activated when the key is turned to the “Ignition” position. The most common and suggested method of connection during a conversion on a four cylinder is to remove the power feed from the original single ignition coil and use it to power all four of the new coil packs.

The wiring for the old harness is as follows:

Cylinder 1

Small Black (with yellow boot under plug) – Ground

Black with yellow stripe – 12 V

Thick Black – Signal

Cylinders 2-4

Small Black (with yellow boot under plug) – Ground

White – 12 V

Red with stripe (stripe colour varies for each cylinder) – Signal

Although there is variation in colour, the 12 V is always the middle wire, ground is always the small black outer wire, and signal is the remaining wire.

On my spare harness, I busted open the factory plugs. It doesn’t matter if you break them, so be firm if necessary. After the yellow central retainer is removed, there will be a small plastic lever that is bent away to allow the corresponding wire to pull out easily. The crimped connectors are very similar to the new ones that will be fitted. The yellow boot on the ground pin can be seen below:

Bend the standard crimped section to reveal as much wire as possible and cut the wire, leaving it as long as you can. Strip back a bit more of the sheathing, slide the new rubber boot over and crimp the connector that came with the new Toyota plugs. I found the ground was so small it needed to be doubled over, and the 12 V wire was so big it hardly fit. Because of this, I ended up soldering over the top of the crimp for maximum reliability.

Using the diagrams above I inserted each wire into the connector until they produced a satisfying click. When looking from the orientation shown in the picture below (release clip up), the sequence is as follows: ground, signal, empty, 12 V. The pictured connector is for cylinder 1.

A bit more electrical tape to tidy and insulate and all the parts are ready to plug and play. Everything looks factory, which is ideal for me. It took me about 90 minutes to change the four plugs. As the standard connectors were disassembled and snipped, the harness length should be close to stock and have no trouble reaching.

Installation

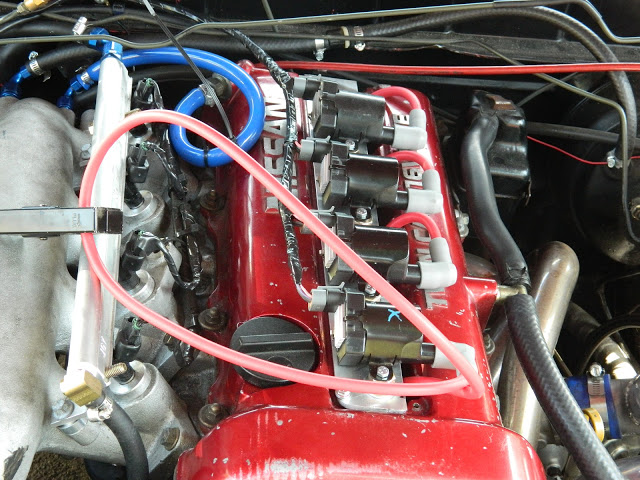

First is the igniter chip bypass. It simply clips in as shown, with a cable tie through the lower bolt hole of the removed igniter to keep it against the edge:

Next is the coil pack harness. The large connector plugs right in, and the ground terminal is secured with a 12 mm bolt near the rear corner of the rocker cover.

Next is the actual coil packs. I purchased the car with some snapped coil pack bolts inside the rocker cover so I’m unable to install the little brackets from Goleby’s at this stage. Number one coil pack is a little tight for clearance on the rocker cover, I’m not sure how well the bracket will fit. Goleby’s does say the kit is for S13 non VTC in fairness. The new coil packs fit more snugly over the spark plugs than the old ones. More force is needed to pull them up and off the top of the spark plugs. The modified harness fits as well as factory.

Start Her Up!

At this point you can verify everything is wired correctly by starting the car. Mine fired up immediately and idled a little smoother than before. Great to know that a lot of research and theoretical knowledge was verified. The car should run and drive perfectly at normal loads without any other changes. This mod isn’t to improve gentle running, however, so an ECU tweak is needed for performance.

Dwell Changes in the ECU

The factory coil packs have a dwell time of 1.9 ms (0.0019 seconds). According to the Toyota coil page linked above, the 1NZ coils need 2-3 ms. Without the ECU tweak the primary coil will not be energised long enough to deliver its full capacity and misfires may still result.

3 ms is 1.5789 times the factory 1.9 ms. I opted to multiply the factory dwell values by 1.5 which will put them at 2.85 ms, with the 2-3 ms range but at the upper end. There are two tables in Nistune for dwell. ‘Dwell time’ sets the dwell vs battery voltage. The lower the voltage, the longer the dwell needs to be to compensate and maintain performance. This is the main alteration required. For each value, multiply by 1.5. If it puts the value over the 255 maximum, enter 255.

The before and after is shown below. The new values are shown in the table and graphed in red. The original values are graphed in purple.

Update: After losing a new coil pack, I have lowered the dwell time. I previous aimed for 1.5 times the factory 1.9 ms (2.85 ms). After some more googling I have now adjusted to be 1.26 times the factory 1.9 ms (2.394 ms). Hopefully this setting is more reliable. Ultimately you want the lowest value possible that still makes enough spark under load at boost. I can always creep it up if the engine misfires.

A second table exists called ‘Dwell duty cycle’. This aims to alter the dwell at specific RPM. It might be adjusted to help at idle or to add some oomph at higher RPM. At this stage I will be leaving it alone.

Test Drive

Wow! The car must have been running sub optimal for quite some time because it really feels amazing now. The engine is smoother in general and there is no longer any hesitation and matching muted engine note on boost. During tuning, winding in boost gave little return, but now there is a clear difference between the 16.5 psi low boost and 21.7 psi high boost. The car really sits me back in the seat, the most it ever has, even on a really hot day. I can’t wait to take it to the drags to see what it can do.

An important point is that I can feel such a distinct difference because the previous coil packs were on the way out. Replacing working units with these would probably only yield results once the boost and power were greatly increased.

Conclusion

If you are starting to push for significantly more power or can sense any form of misfire, this mod is really worthwhile. My new coils are powerful, cheap to replace and give a factory appearance once installed. For $450 (coil pack kit: $270 + Igniter chip bypass: $120 + spare coil pack loom: $40) and about 2 hours of time, the improvement is amazing.

https://sr20tuning.net/mods/ignition-upgrade/

沒有留言:

張貼留言